Vapour Permeability in Semi-Permeable Membranes

Uses, Advantages, Markets, and Standards

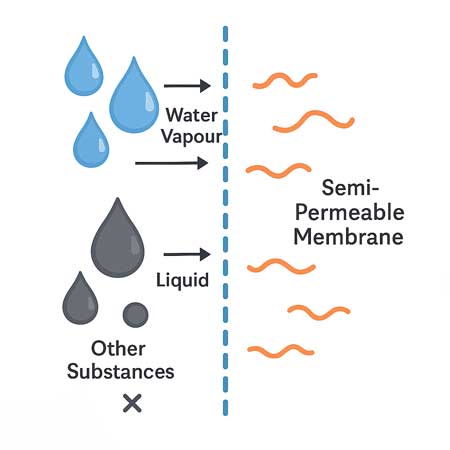

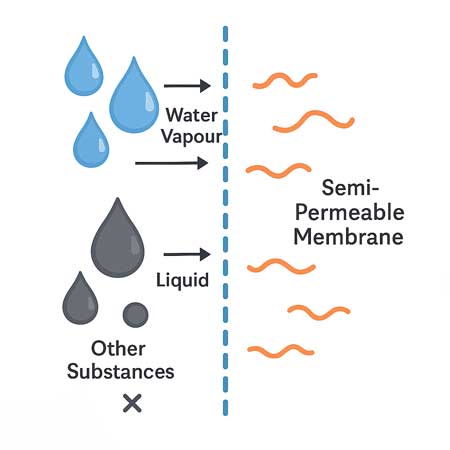

Semi-permeable membranes are materials engineered to allow certain molecules or vapours - most commonly water vapour, oxygen or CO2 - to pass through while blocking others, such as liquids, dust, or larger chemical compounds. Vapour permeability is a critical characteristic of these membranes, and understanding, measuring, and controlling it is vital across a wide range of industries and applications.

Semi-permeable membranes are materials engineered to allow certain molecules or vapours - most commonly water vapour, oxygen or CO2 - to pass through while blocking others, such as liquids, dust, or larger chemical compounds. Vapour permeability is a critical characteristic of these membranes, and understanding, measuring, and controlling it is vital across a wide range of industries and applications.

Advantages of Vapour-Permeable Semi-Permeable Membranes

- Moisture Regulation: These membranes allow water vapour to escape while preventing liquid water from entering, reducing condensation and the risk of mould, corrosion, and structural degradation.

- Breathability and Comfort: In clothing and sportswear, high vapour permeability increases wearer comfort by allowing sweat vapour to escape.

- Barrier Protection: In packaging, semi-permeable membranes can preserve freshness, flavour, and stability while controlling the atmosphere inside the packaging.

- Durability and Energy Efficiency: In building applications, breathable membranes reduce trapped moisture within walls and roofs, enhancing thermal insulation efficiency and building lifespan.

- Selective Filtration and Controlled Exchange: In medical and industrial applications, semi-permeable membranes are used to separate gases or manage fluid and vapour transfer precisely.

Market Areas of Use

- Construction and Building Materials:

- Breather membranes for roofs and façades

- Vapour control layers (VCLs)

- Air and moisture barriers

- Medical and Healthcare:

- Wound care dressings

- Dialysis membranes

- Drug delivery systems

- Textiles and Apparel:

- Waterproof breathable clothing

- Footwear linings

- Technical sportswear

- Food and Pharmaceutical Packaging:

- Modified atmosphere packaging (MAP)

- Breathable films for fresh produce

- Blister packs and sachets

- Electronics and Automotive:

- Vapour venting membranes for battery packs

- Protective casings with pressure-equalising membranes

- Agriculture:

- Greenhouse films

- Controlled release fertilisers and pesticide membranes

Relevant Standards

Various international and industry-specific standards govern the testing and performance of semi-permeable membranes with respect to vapour permeability. These include:

- ISO 15106 Series – Methods for determining water vapour transmission rate (WVTR) of plastic films and sheets

- ASTM E96 / E96M – Standard test methods for water vapour transmission of materials using cup methods (desiccant and water methods)

- EN 12572 – Hygrothermal performance of building materials and products – Determination of water vapour transmission properties

- EN 13726-2 – For medical devices and wound dressings – Measurement of moisture vapour permeability

- BS 3177 – British standard method for determining water vapour transmission through flexible sheet materials

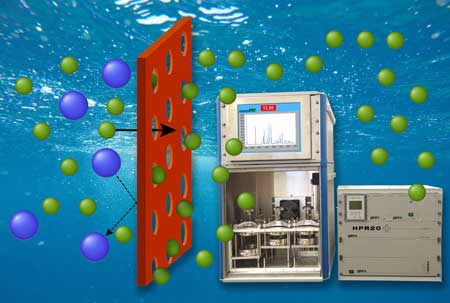

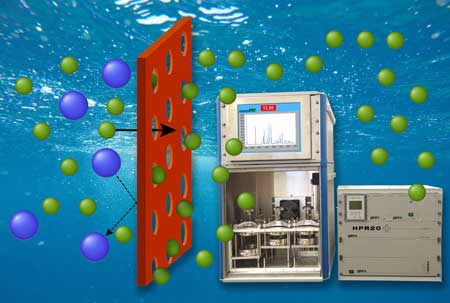

Versaperm’s Role

Versaperm specialises in both the manufacture of high-sensitivity instrumentation and the provision of consultancy services to help customers test, understand, and optimise vapour permeability. Its systems are used to measure transmission rates of vapours—including water, oxygen, CO₂, and others—through semi-permeable membranes, ensuring compliance with relevant standards and delivering critical data for R&D, QA, and product design.

Accurate vapour permeability measurement helps manufacturers select materials, predict performance in real-world conditions, and maintain quality and compliance, offering a distinct competitive advantage in innovation-led markets.

Semi-permeable membranes are materials engineered to allow certain molecules or vapours - most commonly water vapour, oxygen or CO2 - to pass through while blocking others, such as liquids, dust, or larger chemical compounds. Vapour permeability is a critical characteristic of these membranes, and understanding, measuring, and controlling it is vital across a wide range of industries and applications.

Semi-permeable membranes are materials engineered to allow certain molecules or vapours - most commonly water vapour, oxygen or CO2 - to pass through while blocking others, such as liquids, dust, or larger chemical compounds. Vapour permeability is a critical characteristic of these membranes, and understanding, measuring, and controlling it is vital across a wide range of industries and applications.